Several Factors Affecting the Performance of the Solar Road Stud.

Solar road stud is a type of road stud installed along the road surface. Composed of the retro reflective material, shell, solar panels, LED, control devices, the solar road stud plays an important role in outlining the shape of road, indicating the direction of the road, night or rain and fog weather as well as in the corners of the road induce the vision of drivers so as to eliminate the safety risks. This article will discuss several aspects of measuring the performance of solar road stud.

Compressive Capacity

The solar road stud would be easily smashed by the running-over of vehicles if it can not withstand a certain level of pressure, thus failing to work. Therefore the compressive capacity is a cardinal quality for the solar road stud. The solar road stud is an electronic product to begin with, containing electronic parts, it’s not easy to make the electronic part have a high degree of compression performance. Generally the performance of compressive strength of the solar road stud is inferior to the normal type.

Sealing Performance

A solar road stud not well sealed means possible water seepage, which will causes short circuit and brings about terrible consequence. Therefore a qualified solar road stud must possess good sealing performance.

Brightness

The solar road stud actively glows and clearly outlines the contour of the road; It is very important that the luminous intensity is high compared with the ordinary reflective road stud. In this respect the requirement of the Ministry of Traffic is 200 MCD.

Battery Life

The duration of the battery inside the solar road stud is an essential factor deciding the service life of the stud, so it is of great importance to use the battery that not only possesses long span but also can work in a relatively dramatic range of temperature.

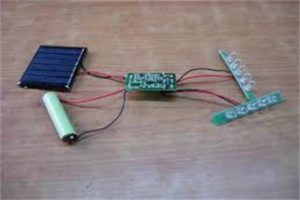

Circuitry

The design of the circuitry should abide by the principle of simple and effective. The unnecessary

Complexity should be avoided for one more circuit means one more chance of fault. Besides, extra attention is needed when selecting electronic component because the breaking of a single component might paralyze the whole system.

Welding

It is vital to make sure the welding of the stud is solid. Since the road stud bears the rolling and impact of numerous vehicles, a loose welding will inevitably lead to the falling off of the circuit. It is necessary to choose the high quality welding gun and soldering tin when install the stud to ensure a solid welding work preparing the stud for the harsh working condition.

Solar Panel

Solar panels directly absorb solar energy and convert light energy into electricity, which is the first link in the whole working system of the solar road stud; it directly determines the efficiency of the solar road stud. Solar panels must be of high hardness and wear-resistance. Solar panels have to withstand the roller wear of the wheel every day, if the strength is not enough, it is easy to wear flowers, and then affect the conversion efficiency of solar panels. The solar panel wears easily and consequently harm the conversion efficiency if is under capacity for it is run over by a considerable numbers of cars.